Top 10 Tips To Determine The Frequency Of PAT Testing in Leamington Spa

The UK's health and safety laws make it difficult for duty holders to determine the right frequency of Portable Appliance Testing. Contrary to widespread misconception, there is no mandated statutory interval–such as an annual requirement–specified in the Electricity at Work Regulations 1989. Regulation 4(2), however, imposes the general duty of maintaining electrical systems for safety, placing legal responsibility on the employer to create a suitable maintenance program through a risk assessment. Health and Safety Executive has endorsed this risk-based method, which moves away blanket testing schedules and mandates a justifiable, documented explanation for all inspection and tests intervals. The frequency is determined by evaluating what type of equipment it is, the operating environment in which it operates, who uses it, and how long ago that was.

1. Risk Assessment Is the Absolute Primeval Factor

The frequency for testing is not dictated by law. However, the dutyholder must conduct a sufficient and appropriate risk assessment. This assessment will be the foundation for all your PAT tests. This assessment must take into account all the factors that can cause an appliance become dangerous, and determine how often they should be tested and/or inspected to reduce that risk. An inspector from the HSE will expect to see this assessment and will judge the testing frequency against its conclusions. This assessment is vital to the testing schedule.

2. Key Factors Influencing Testing Intervals

Risk assessment is required to evaluate the core factors in order to determine an acceptable testing frequency. These include: Equipment Type: Class I appliances (e.g., kettles, toasters, power tools) require more frequent testing than Class II (double-insulated) appliances due to their earth reliance. The environment: An adverse setting (such as a construction site or workshop) requires more frequent testing than an office. Equipment that is used by employees who are trained may require less formal testing. This will be the case for equipment that is used by untrained or public staff. Appliance construction: More robust equipment is less likely to be a risk. A device with a history of problems will need to be checked more often.

3. The Role of Formal Inspections

Visual inspections, which are legally required as part of maintenance procedures, are more important that combined inspections. They can detect most faults including cable damage, loose connectors, casing damages, and contamination. For many low-risk appliances in low-risk environments (e.g., a desktop computer in an office), a formal visual inspection by a competent person may be all that is required, with no need for routine electronic testing. The risk assessment will also determine the frequency of formal visual inspections.

4. User Checks and First Line Maintenance

User checks are the first line in defence before any formal process. The dutyholder should ensure that users are encouraged by the dutyholder to perform a simple pre-use inspection, looking for obvious signs such as frayed cords, burn marks, and loose parts. The PAT system does not record user awareness, but it is an important part of a holistic approach to risk and can identify problems in between scheduled inspections.

5. Guidance from the IET Code of Practice

It is important to note that the IET Code of Practice does not constitute law. However, it offers valuable guidance as to recommended first frequencies. It offers a comprehensive table suggesting intervals for different equipment types in various environments (e.g., commercial, industrial, public). Dutyholders can use this table as a robust starting point for their risk assessment. It might, for example, suggest that equipment on a building site be visually inspected every three months but IT equipment in a office is inspected at intervals of 24 months. These are initial recommendations to be adjusted based on actual experience.

6. The Concept of Result-Based Frequency Scheduling

The results of the previous tests can be used to adjust future test frequencies. The risk assessment can then be reviewed in order to justify an increase in the testing interval if an appliance or category of appliances consistently passes their tests without error over a period of several years. In contrast, if an appliance type is prone to failure, the interval can be shortened. The enforcement authorities are very supportive of this dynamic and evidence-based approach.

7. New Appliances and Equipment

A common misconception is that all new equipment must be tested. It may not require a formal combined testing before the first use but a visual inspection will still be required to check the equipment for transit damage, the correct wiring of the plug and its suitability for the UK (e.g. a properly fused plug). The risk analysis will determine when to test new equipment. It will be integrated into the maintenance schedule.

8. Hired or Borrowed equipment

Equipment brought into the building, such as tools hired by contractors or equipment they use, must be added to the PAT. It is the dutyholder's responsibility to make sure that it is safe for use before using. It is common for risk assessments to be conservative. This means that they require a formal inspection and test before it can be used on site.

9. Documenting the Justification for Frequencies Chosen

Compliance is demonstrated through documentation. The risk analysis must not only record the frequency selected for each appliance but also include the reasoning that led to this decision. This document serves as proof of "due diligence." This document should list the factors to be considered (environment type, user, and equipment type), as well as, if appropriate, reference the IET Code of Practice.

10. Regular Review & Adjustment of Intervals

Risk assessments and the test frequencies they dictate are not static. Regulation 4 of 1989 Electricity at Work Regulations requires that maintenance be carried out continuously. The dutyholder should review the risk assessments and effectiveness of testing intervals regularly (e.g. annually) or following any significant changes, such as near-miss incidents, equipment changes, or changes in the workplace. This ensures that the system remains proportionate and effective. Check out the best PAT testing in Leamington Spa for blog tips.

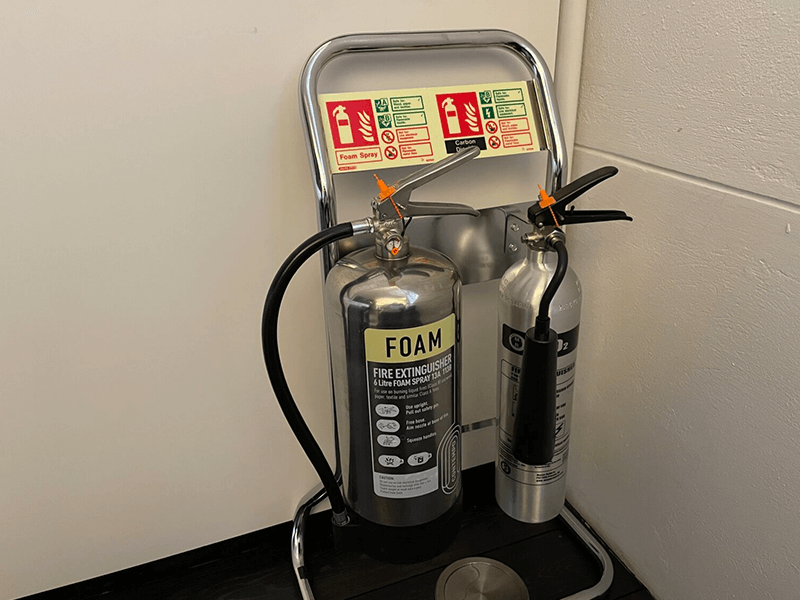

Fire Extinguisher Servicing Ten Tips To Help You Service Your Fire Extinguisher in Leamington Spa

There's more to selecting a UK-based maintenance company than just finding someone who will perform an annual test. Comprehensive providers act as a single-point of contact for managing your entire inventory of fire safety equipment. They provide an integrated service that can reduce administrative burdens and provide the complete solution. The range of services offered is a clear indicator of the knowledge and capabilities of a provider as well as their determination to become a trusted partner instead of just a contracting company. Understanding the complete range of services offered starting with risk assessments and installation, through ongoing maintenance, through emergency support and disposal at the end of life, allows you to make informed decisions that ensure both safety and efficiency.

1. Routine Maintenance and Scheduled Services Routine Maintenance and Scheduled Service: This is a fundamental service that strictly follows the BS 536-3. A full-service company manages all scheduled intervals, including monthly visual checks, which are typically supervised by the customer with the help of the service provider. They also provide the annual, mandatory, basic maintenance for extinguishers as well as the extended service, also known as discharge test for powder, water, and foam models every 5 years and the overhaul/pressure test as well as overhaul of CO2 extinguishers every 10 years. These visits should be planned ahead of time, and with complete certificate for each.

2. The correct equipment is supplied and set up by a quality service provider. They do not only provide maintenance, but they also provide advice and the right equipment. This service includes performing a survey of your premises to determine which extinguishers you need based upon the risk assessment for fire as well as the specific dangers that exist (e.g. class A, B, C, F electrical). The company will supply certified equipment that is BSI-Kitemarked and will install them according in accordance with the requirements set forth in the BS 5306-8. This includes proper installation, signage, and accessibility.

3. Fire Risk Assessment: Many of the leading service companies employ assessors who are certified to complete or revise your legally-mandated Fire Risk Assessment. It is essential that this is an independent procedure. If your extinguisher provider contributes to or completes the FRA it will ensure a fully-integrated approach in which equipment selection is directly linked to the identified risks. It creates an audit trail that is continuous, starting with hazard identification and ending with control measure implementation.

4. Emergency Callout and Reactive Maintenance: Equipment could be damaged, stolen or discharged accidentally at anytime. A reputable company offers prompt emergency call-out services to quickly replace or recommission equipment, ensuring your premises are never left in a state of non-compliance or without security for more than it is needed. This can include urgent replacements of equipment that has been damaged or are missing.

5. Other Fire Safety equipment servicing The strategy you employ to protect yourself from fire extends beyond portable extinguishers. A full-service company will be competent to maintain and certify every other piece of equipment. You can make one contract that is simple to manage. This includes dry/wet risers, hose reel systems fire alarms, emergency lighting and. This ensures consistency and reduces paperwork and often helps reduce the overall cost.

6. Education and training services The only way to ensure that the people who use it are able to use it, will the equipment work effectively. Numerous service providers offer complimentary training and education services, such as fire extinguisher training (often with live fire simulations), training for fire wardens and sessions on general fire safety awareness. This empowers your staff, enhances overall safety, and also demonstrates your commitment to adherence.

7. Comprehensive online portals for documentation. The need for robust records is required to be kept by law. Not only documents on paper, but sophisticated documentation is provided by leading companies. These include detailed digital reports on service and asset registers. You can also access online customer portals for customers to check your service history, download your certifications, report faults and schedule appointments.

8. Disposal and Environmental Services: The proper disposal of decommissioned extinguishers in accordance with Duty of Care is a significant environmental and legal requirement. A full-service service provider can do this efficiently using certified waste carriers and will provide Waste Transfer Notes, which are proof of legal, correct disposal. Avoid the high fines associated improper disposal pressurised vessels or hazardous materials.

9. Planned Preventative Management and Asset Management. Beyond reactive calls, the best companies offer proactive PPM plans. They will manage your entire portfolio of assets, including monitoring due dates for services for different equipment types and automating the scheduling of visits. It takes away the administrative burden and ensures that there is no service is missed.

10. Consulting and Compliance Auditing For larger or more complex sites, expert providers offer consultancy services. This may include an assessment of your current fire protection measures in relation to the legal standards. It can also involve giving advice on plans for remedial measures and providing ongoing auditing of compliance. Check out the best fire extinguisher servicing in Leamington Spa for blog examples.